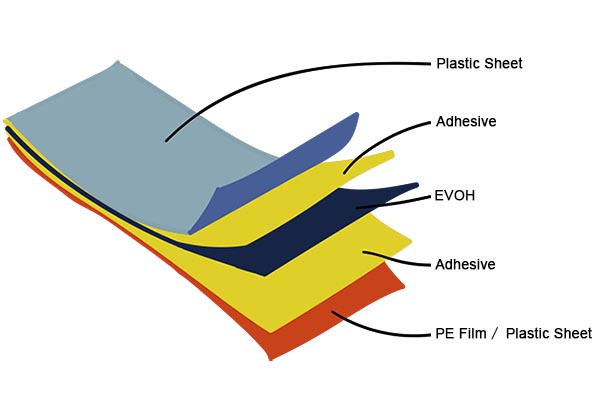

Da farko, damultilayer co-extrusionjuriya diaphragm fim ne na filastik.A fagen samfuran filastik, yawanci muna magana ne akan samfuran filastik da kauri ƙasa da 0.2 mm azaman fina-finai na filastik, waɗanda ke da kauri tsakanin 0.2 da 0.7 mm azaman zanen filastik da waɗanda ke da kauri sama da 0.7 mm azaman faranti.Multilayer co-extrusion juriya diaphragm zai sami takamaiman aikin shingen gas.Shamaki a nan yana nufin iyawar garkuwar kayayyakin robobi (kwantena, fina-finai) da ƙananan iskar gas da wari.Yawancin lokaci muna amfani da iskar gas don auna iyawar samfuran filastik.PE, PP da sauran robobi na gabaɗaya suna da ƙima mai girma na iskar gas, wato, iskar gas ɗin ba shi da kyau, yayin da PA, PVDC, EVOH da sauran kayan guduro suna da ƙarancin ƙarancin iskar gas fiye da robobi na gabaɗaya, kuma iskar gas yana da kyau.Saboda haka, mu yawanci kira damultilayer coextrusion fimmai ɗauke da aƙalla kayan guduro guda ɗaya na PA, PVDC da EVOH a matsayin diaphragm ɗin juriya na haɗin gwiwa da yawa.PE, PA, TIE, EVOH da sauran resins za a iya amfani da su don marufi na kayan kiwo, jam, kayan nama, da dai sauransu.

Multilayer tare-extruded fina-finaigalibi suna ɗaukar tsarin simmetric Layer Layer ABCBA5, tare da PA ko EVOH azaman shinge mai shinge da polyethylene azaman Layer hatimin thermal.Ana amfani da guduro mai mannewa don raba shingen shingen da ba a haɗa da shi ba da Layer hatimin zafi.PA ko EVOH yana da matuƙar kula da zafi, ana kiyaye shi ta hanyar polyethylene Layer, kuma kyakkyawan aikin shingen iskar oxygen an haɓaka shi sosai.Gaba ɗaya, tsarinmultilayer co-extruded fimya dogara da bukatun aikin fim.A kan yanayin saduwa da buƙatun tsari, haɗuwa da nau'ikan polymers daban-daban na iya saduwa da buƙatun aiki na kayan marufi kamar shamaki, rufewar zafi, ƙarfin jiki, huda thermal, daidaitawar muhalli, halayen sarrafawa na biyu da haɓakar ajiya da rayuwar shiryayye.Daga hangen nesa na buƙatun aiki, haɗuwa da polymers biyar ya isa.Duk da haka,fim ɗin da aka haɗa taretare da nau'i bakwai, tara, goma sha ɗaya ko fiye da aka yi amfani da su a kasuwa wanda ya sa ya zama mai tasowa kuma yana tasowa cikin sauri.Tsarin tsari na fim ɗin haɗin gwiwa yana buƙatar sannu a hankali don cimma kyakkyawan yanayin haɗakar aiki, fasaha, farashi, kare muhalli, aminci da aiki na biyu.

1. Kwatancen farashi

Yin amfani da polymers masu rahusa a saman maimakon polymers masu tsada na iya rage farashin kayayyaki kuma yana da aikin rufewar zafi da kuma juriya mai girma na polymers sarkar ionic.Don kayan da ke da shinge iri ɗaya da zafi-hatimin iyawar 7-Layer co-extrusion hurawa fim ya fi tattalin arziki fiye da 5-Layer fim.

2. Shamaki

Yin amfani da nau'i-nau'i daban-daban guda biyu maimakon polymer guda ɗaya a kan shingen shinge na iya inganta kayan katangarsa sosai.Alal misali, haɗin EVOH Layer da kayan nailan na yau da kullum ba zai iya kawai kula da penetrability na PA ba, amma kuma yana ƙara ƙarfin EVOH da inganta juriya na EVOH saboda Layer EVOH yana sandwiched tsakanin nau'i biyu na PA amine, yana sanya shi. fim ɗin tare da babban shinge, yayin da fim ɗin haɗin gwiwa na Layer biyar ba za a iya cimma ba.Ana iya ƙara yawan kuɗin ƙara EVOH zuwa yawan amfani da tsarin.Matsakaicin watsa iskar oxygen na fim ɗin haɗin gwiwa guda biyar tare da tsarin 20% PA shine raka'a 3.5, amma a ƙarƙashin yanayi guda, yawan watsawar EVOH da aka ƙara zuwa fim ɗin Layer bakwai shine raka'a 0.13.

3. Tsagewar juriya

Ana iya inganta kaddarorin fina-finai tare da PA tare da ƙarin yadudduka.Alal misali, yin amfani da ƙarin manne-kwane zai iya inganta aikin shinge na fim ta hanyar ƙara tasirin tururin ruwa na fim din.Wani amfani da aka samu a lokaci guda shi ne cewa zai iya sa fim din ya zama mai laushi, jin dadi kuma yana da kyakkyawar juriya.

Tare da ci gaba da ci gaba da fasaha na fasaha na polymer, za a iya amfani da sababbin polymers tare da kayan aikin jiki na musamman da na inji don saduwa da bukatun marufi.Aiki da tsarin namultilayer co-extruded hadaddun substrate fimzai sami babban sassauci da tattalin arziki.Ta hanyar aikace-aikace da haɓaka kayan gyare-gyare da fasaha, haɗe tare da keɓaɓɓen kuma ingantaccen ƙira na tsarin haɗin gwiwar, masana'antun fim za su sami rawar juyin juya hali a cikin bin da yanayin tunani na ra'ayoyin diversification na marufi ayyuka, rationalization na marufi tsarin, da kuma maximization na marufi amfanin.

Lokacin aikawa: Afrilu-17-2023